Tel: +86-150-1280-2327 Email: granitecomponents@163.com

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

English

English English

EnglishViews: 0 Author: Site Editor Publish Time: 2025-08-06 Origin: Site

When you test a semiconductor, you use special tools to check how it works. Good testing helps you find problems and weak chips before they are sold. This keeps devices safe in places like hospitals and airplanes. High-quality semiconductor testing equipment gives you exact results, so you can trust your tests. Granite measuring platforms and granite equipment bases help your tests by giving a steady surface. This keeps your measurements correct and the same during every part of testing.

Use special tools like probe stations and parameter analyzers to test semiconductors. Granite platforms help make tests more accurate and reliable.

Follow simple steps when testing: clean the chip, set up the tools, do electrical and functional tests, and write down the data carefully.

Check your equipment often to make sure it works right. Granite bases help keep the setup steady and lower mistakes. This helps you get the same results each time.

Keep the testing area under control. Watch the temperature, humidity, and vibration. This helps stop errors and makes tests better.

Take care of your equipment and fix problems fast. This keeps tests working well and makes sure your results can be trusted.

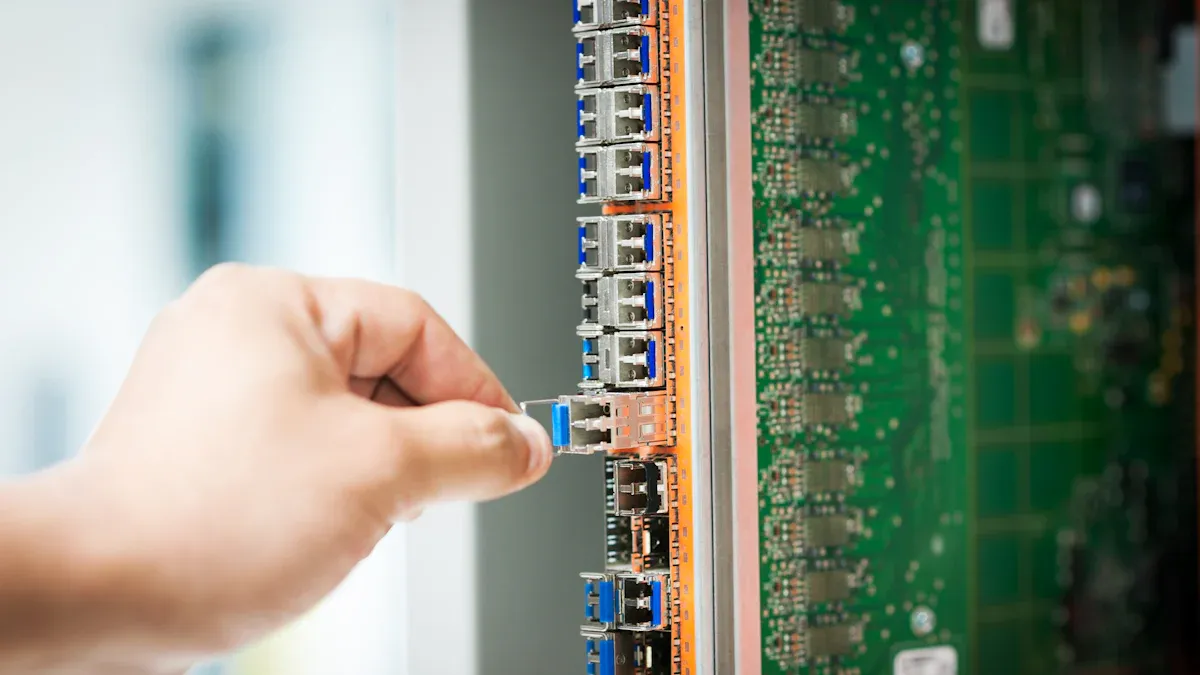

Probe stations and wafer probers help test semiconductor wafers. These machines keep the wafer still on a wafer chuck. Thin probe needles or probe cards touch small pads on each chip. This setup lets you test wafers with great accuracy. Probe stations check if each die works well. Automated wafer probing puts probes in place fast and right. This saves time and helps you spot weak chips early.

Parameter analyzers check things like voltage and current. You use them to see if a semiconductor works as planned. Automated Test Equipment, or ATE, does even more. ATE systems run lots of tests by themselves. They use hardware, software, and special tools to control signals and gather data. You can test memory chips, analog chips, and logic chips with ATE. This equipment makes testing semiconductors quicker and more trustworthy.

Granite platforms and bases give a strong surface for testing equipment. Granite is very stiff and does not shake much. This is important because small shakes can change your results. Using a granite equipment base gives you better and steady results. Granite measuring platforms and granite optical platforms from SYIN Automation Technology Co., Ltd. help keep your setup steady and exact.

Tip: Granite mechanical parts help stop mistakes from shaking or temperature changes during wafer testing.

You also need other tools and accessories for testing semiconductors. These include testing sockets, probe cards, sensor chips, and measuring tools. Granite measuring tools, like granite parallel rules and granite square rulers, help you set up your equipment very well. These tools make sure your measurements are right every time you test a semiconductor.

Testing a semiconductor has many steps. You must follow each step to get good results. This process helps you find problems early. It also makes sure every chip works right.

First, get your semiconductor ready for testing. Clean it to take away dust or dirt. Even tiny dirt can change your results. Put the semiconductor on a strong platform. A granite measuring platform from SYIN Automation Technology Co., Ltd. keeps it steady. This helps you avoid mistakes.

Then, connect the semiconductor to the test equipment. Use probe stations or wafer probers to touch the chip. Pick the right sockets and probe cards. Before you start, check and set your equipment. Calibration is very important for good results. It helps you see even small changes in signals. You can find bad chips early and waste less. Calibration makes sure your tests follow the rules. It also helps you watch the whole process.

Good parametric testing needs well-set equipment and exact probes.

Calibration helps you find small changes in electricity.

You can make fewer mistakes by checking your tools before each test.

Tip: Always use the same setup steps. This makes your tests repeatable and trustworthy.

After setup, you can do the main tests. The process uses different tests to check your device. You must do both electrical and functional tests.

Here is a table of common tests you will use:

Test Category | Common Tests Included |

|---|---|

Electrical Tests | DC Parametric Testing, AC Parametric Testing, Electrostatic Discharge (ESD) Testing, Thermal Testing, |

Time-Domain Reflectometry (TDR) Testing, Radio-Frequency (RF) Testing, Noise Figure Testing, | |

Power Supply Noise Testing, Signal Integrity Testing | |

Functional Tests | Functional Testing (verifies device operates as intended) |

DC and AC parametric testing measure voltage, current, and resistance. ESD testing checks if your chip can handle static. Thermal testing shows how your chip works in hot or cold. RF and signal integrity tests check if your chip handles fast signals. Functional testing makes sure your chip does its job.

You should use a granite optical platform or granite equipment base. This keeps your setup steady during tests. It helps you avoid mistakes from shaking or moving.

When you finish the tests, write down and study the data. Good data recording is very important. You want to catch every problem.

Follow these steps for good data recording and analysis:

Use smart analytics and machine learning to look at lots of test data. This helps you guess yield and find problems early.

Watch sensor data from your tools. This helps you see warning signs and stop downtime.

Use real-time feedback to change your testing. This keeps your results correct.

Use high-resolution imaging and machine learning to find and sort defects fast.

Data analytics uses math and artificial intelligence to help you control testing. By collecting data from sensors and tools right away, you can find problems early and fix them fast. This way gives you better control than just checking samples after testing.

Note: Always use the same rules for data recording and analysis. This makes your results reliable and helps you get better at testing over time.

By following these steps, you make sure your testing is correct and repeatable. Using good platforms and tools from SYIN Automation Technology Co., Ltd. helps you get the best results every time.

You can get better testing results by using good habits. First, make a clear test plan that fits your device and follows industry standards. This plan helps you check every important step. Calibrate your equipment often to keep your measurements correct. When your tools are set right, you make fewer mistakes from drift or noise. Keep your test data safe and organized. Good data management helps your results stay true and trusted. Automation lets you do the same test many times, fast and with care. You can use granite measuring tools and granite optical platforms from SYIN Automation Technology Co., Ltd. for a steady setup. Always check your rules and teach your team to keep your testing strong.

Following industry standards helps you follow strict rules in healthcare and aerospace. These standards guide your steps and help you earn trust from customers.

Best Practices Checklist:

Make a clear test plan.

Calibrate your equipment often.

Keep test data safe and neat.

Use automation for repeated tests.

Teach your team and update your rules.

You can stop mistakes in testing by controlling your space and setup. Temperature, humidity, and vibration can change your results. Use a granite equipment base to stop shaking and keep your setup steady. The table below shows how different things in your space can change your test results:

Environmental Factor | Impact on Testing | Reliability Tests Used |

|---|---|---|

Temperature | Can cause cracks and chip failures | Thermal Cycle, HAST |

Humidity | Can lead to corrosion and failures | PCT, THB, UHAST |

Mechanical Stress | Can cause cracks and defects | Vibration, Shock, Bending Tests |

Moisture Absorption | Can raise the risk of corrosion | Preconditioning, PCT |

Always keep your work area clean and free from dust. Check your connections and use the right sockets and probe cards. By doing these things, you lower mistakes and get better results.

Repeatability means you get the same results each time you test. To do this, keep your testing conditions the same every time. Use the same method, equipment, and place for each test. Test many samples, usually 20 or more, to check your results. Use simple math tools like standard deviation to see if your results match. Train your workers well and calibrate your tools often. Granite platforms and bases help keep your setup steady, which is important for repeatable results.

Tip: Do not change your setup between tests. This helps you stop new mistakes and keeps your results trusted.

By using these tips, you can make your testing better and make sure your results are right and repeatable. Using strong granite platforms and other products from SYIN Automation Technology Co., Ltd. helps you get the best results.

Sometimes, your equipment may have problems during testing. These problems can stop your work or give wrong results. You can stop many problems with regular checks and care. Here are some steps you should follow:

Look at and fix your equipment before it breaks.

Calibrate your machines after you set them up or move them.

Clean your tools to get rid of dust and dirt.

Change old parts and check all wires and plugs.

Oil moving parts and check safety features.

Write down every time you do maintenance.

Doing regular checks helps you stop sudden breakdowns. This keeps your test setup working well and saves you time and money.

Granite measuring platforms and granite optical platforms from SYIN Automation Technology Co., Ltd. give a steady base. This cuts down on shaking and helps your equipment last longer.

Sometimes, your measurements are not right during testing. These mistakes can come from bad calibration, temperature changes, or people making errors. You can find and fix these problems with good tools and habits.

Use metrology tools like optical microscopy or atomic force microscopy to check your results.

Use more than one tool to double-check your measurements.

Calibrate your tools often to stop drift.

Keep your room at the same temperature and stop shaking.

Pick the right probe size and filters for each test.

AI-powered inspection systems can help you find defects fast and keep your results correct. Granite measuring tools help you get more correct and repeatable data.

Sometimes, you get results that do not match what you expect. First, check your setup and all connections. Make sure you do the same steps for every test. Look at your test setup and see if anything changed.

Step | What to Check |

|---|---|

Equipment | Calibration, cleanliness, connections |

Environment | Temperature, humidity, vibration |

Test Procedure | Probe placement, sample preparation |

Data Analysis | Software settings, data logs |

If you still get strange results, try a new sample or do the test again. Using a steady granite platform can help you stop errors from shaking or moving. Always keep your workspace clean and follow your normal steps.

Tip: Careful troubleshooting helps you keep your testing reliable and your results trusted.

You can get good results if you follow every step. Use granite platforms and granite measuring tools to keep your setup steady. Granite bases are strong and do not wear out fast. They also do not rust or change with heat. This helps you get the same data each time.

Reliability testing, like burn-in and temperature cycle tests, helps you find weak spots and make devices better.

Training and certification programs, like those from SEMI University, teach you real skills for advanced testing.

If you follow best practices and use the same steps, you get more good chips, spend less money, and do well in the industry for a long time.

Semiconductor testing checks if chips work the right way. It helps you find weak or broken chips before customers get them. This makes your products safe and dependable.

A granite measuring platform gives a flat, steady place to test. This helps you get results that are right every time. Granite does not bend or shake, so your measurements stay the same.

You should calibrate your equipment before every test session. Doing this often helps you find small mistakes early. This keeps your semiconductor testing results correct and trusted.

You can use granite optical platforms and granite measuring tools. These help you set up your equipment very carefully. They also help stop shaking and make your tests more exact.

Yes, you can use granite mechanical parts in medical devices, aerospace, and precision factories. Granite bases and platforms help with careful work in many jobs.

Tip: Visit SYIN Automation Technology Co., Ltd. to see more granite solutions for your testing needs.