Tel: +86-150-1280-2327 Email: granitecomponents@163.com

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

English

English English

EnglishViews: 0 Author: Site Editor Publish Time: 2025-08-11 Origin: Site

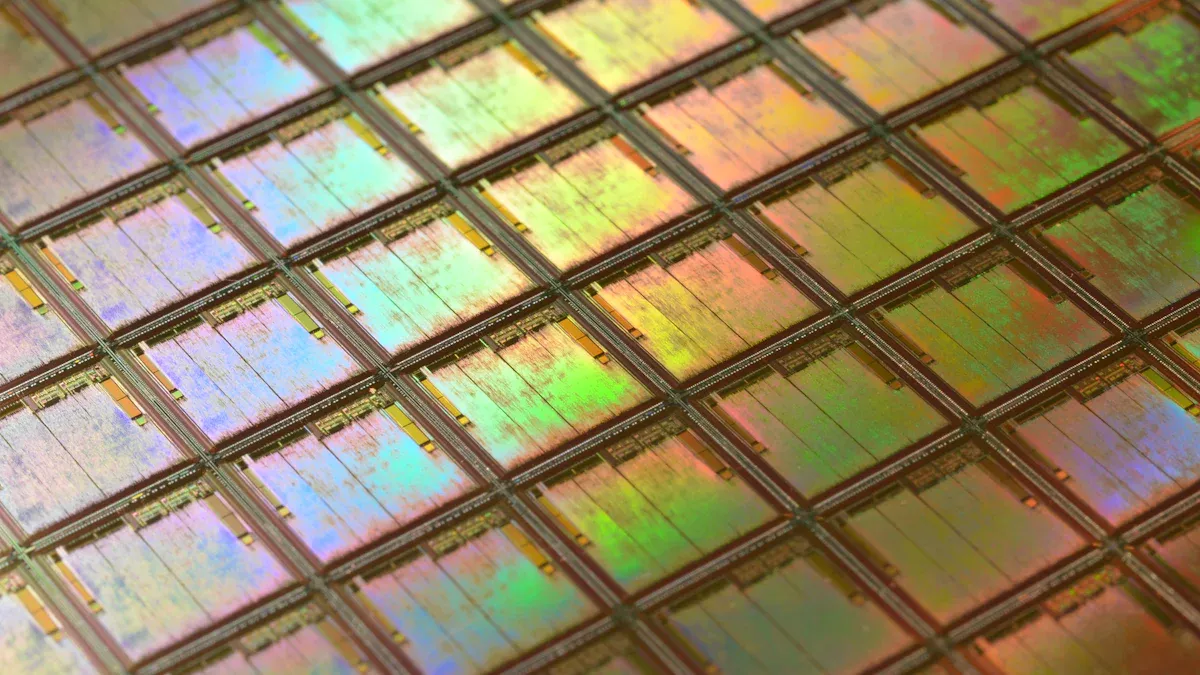

Chips are closely spaced, so wafer dicing equipment must ensure exact cuts to maximize material usage.

Careful dicing reduces debris and contamination, resulting in higher quality chips.

A stable wafer dicing process leads to increased yield and improved device performance.

Wafer dicing cuts wafers into single chips very carefully. This helps protect the chip edges and makes the chips better. Granite bases and measuring platforms keep the machines steady. They lower shaking and help make exact cuts. There are different ways to dice, like using a blade, laser, or plasma. Each way works best for certain materials and needs. Each has its own good points. Using steady machines and careful dicing helps make more chips. It also lowers mistakes and saves money. Good wafer dicing tools and steps help companies make better chips faster. The chips also work better and are more reliable.

Wafer dicing is very important for making good dies from silicon wafers. The equipment must cut each wafer into single dies with great care. If the cuts are not exact, the die edges can get chipped or cracked. Small cracks can also form if the machine is not set up right or if the blade is old. Vibrations during cutting can also cause these problems. When a die has chips or cracks, it might break later during packaging or when used. This makes the final product less reliable.

Other problems can happen too, like burrs and tiny particles. Burrs are small pieces left on the die after cutting. They can make it hard to handle the die and might even cause short circuits. Tiny bits of silicon or tape can stick to the die and hurt how it works. Sometimes, tape can peel off or a die can fly off if the process is not steady. This can cause dies to be lost and fewer good dies made. To stop these problems, companies use granite bases and granite measuring tables from SYIN Automation Technology Co., Ltd. These granite parts keep the machine steady and help make sure each die is good.

Tip: Good dicing machines with granite parts make sure cuts are exact and keep each die safe.

Good wafer dicing helps make more chips faster. When the dicing process works well, it cuts wafers into dies quickly and neatly. Newer ways to dice, like plasma dicing, make cleaner cuts and less mess. This helps when working with bigger and thinner wafers, so more dies can be made from each one.

Some machines can cut many wafers at the same time, which saves time. These better dicing methods help make more good dies and lower costs. Companies can make more small and energy-saving chips by using fast dicing systems. Granite bases and measuring tables keep the machines steady, which is needed for fast and careful cutting. Because of this, making chips becomes quicker and companies can earn more money.

The dicing process changes a whole wafer into many dies. Every step needs to be very exact. Granite bases and granite measuring platforms help keep things steady. They also lower vibration during each part of the process.

First, workers clean and check the wafer for dust. Then, they put the wafer on sticky dicing tape. This tape holds the wafer in place. The tape sits on a metal frame for extra support. The wafer must not move while dicing. Granite platforms keep the wafer flat and safe. This helps make sure the next steps are very exact.

Cutting is the main part of dicing. Technicians set up the dicing pattern in the machine. The pattern matches the circuits on the wafer. The machine uses a blade, laser, or plasma to cut. Each cut must be perfect to protect the die edges. The kerf is the width of each cut. It should be small to save material. Granite bases soak up vibrations from the tool. This keeps the wafer steady for straight cuts. Good cutting gives better dies and more of them.

Tip: Granite parts in dicing machines lower vibration and keep the wafer in place during cutting.

After cutting, workers separate the dies. They gently push or bend the dicing tape. The way they do this can make more or fewer particles. Blade dicing makes more particles. Laser and plasma dicing make less mess. A special coating can catch particles, which are cleaned off later. The room must be very clean to stop contamination. Granite platforms help during separation. They lower chipping and keep particles down.

Best ways to separate dies:

Use laser or plasma dicing for cleaner dies.

Put on coatings to catch particles.

Work in a cleanroom.

Clean gently to protect the die surface.

The last step is cleaning and checking the dies. Workers use deionized water and gentle cleaning to remove particles. Harsh cleaning can hurt the dies, so gentle ways are better. After cleaning, each die is checked carefully. Technicians look for cracks, chips, or other problems. They use special tools and microscopes to check each die. Granite platforms give a steady place for inspection. This helps get good measurements and results.

Step | Purpose | Key Equipment/Component |

|---|---|---|

Wafer Mounting | Hold wafer for dicing | Granite platform, dicing tape |

Cutting | Cut wafer into dies | Dicing saw, granite equipment base |

Die Separation | Separate single dies | Granite measuring platform |

Cleaning & Inspection | Clean and check die quality | Megasonic cleaner, inspection tools |

The dicing process needs to be steady and exact at every step. Granite parts from SYIN Automation Technology Co., Ltd. help reach these goals. They make sure each die is cut, separated, and checked with great care.

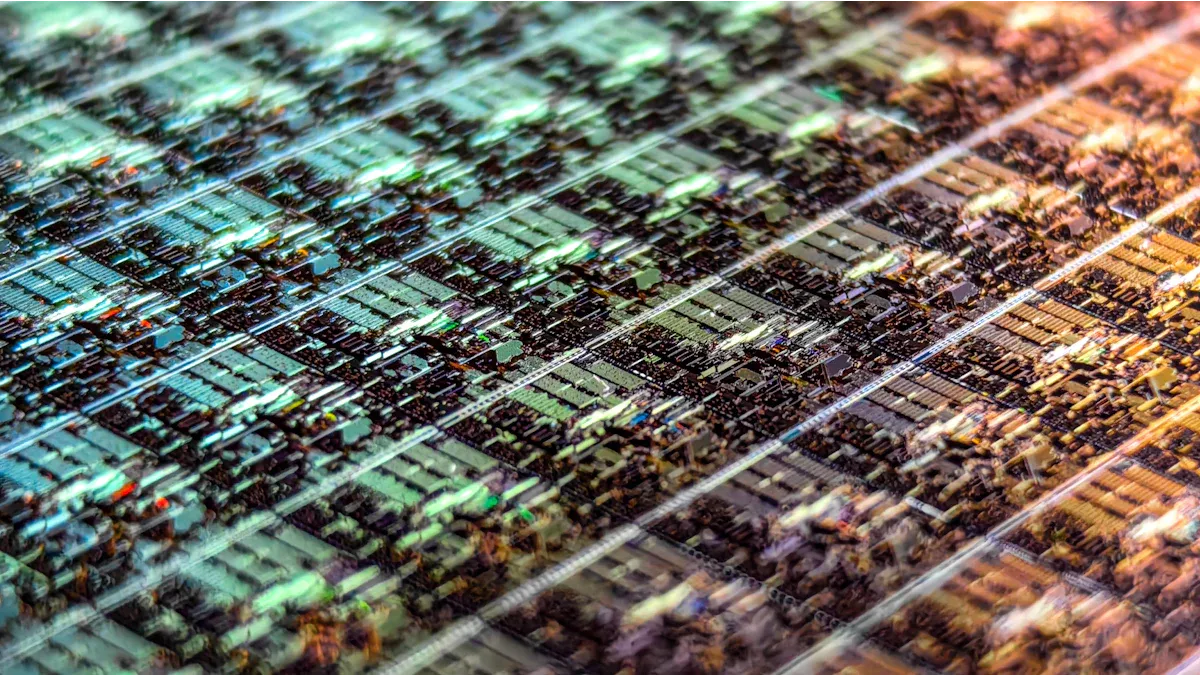

The semiconductor industry uses different ways to cut each die from a wafer. These ways include mechanical blade, laser, and plasma dicing. Each way has special features and works best for certain chips and materials.

Mechanical blade dicing is the most used way to cut wafers. It uses a fast spinning blade to slice the wafer on marked lines. This way is good for hard and breakable materials like silicon and alumina. Mechanical blade dicing makes many dies quickly, so it is good for making lots of MEMS and ICs. But it can cause chipping, tiny cracks, and debris. To help stop these problems, companies use granite equipment bases and granite measuring platforms from SYIN Automation Technology Co., Ltd. These granite parts keep the saw steady and lower shaking, which helps protect each die.

Laser dicing cuts the wafer with a focused laser beam. The laser does not touch the wafer, so it lowers stress and the chance of chipping. Laser dicing is good for thin wafers and special materials. It can make thin cuts, which saves more material and makes more dies per wafer. But it can be hard to use on rough or heavily doped wafers. Granite platforms give a steady base for laser dicing machines, so cuts are clean and lined up right.

Plasma dicing uses a dry etching process to cut each die. Plasma etches away the wafer along the dicing lines. Plasma dicing is good for narrow spaces and tall chip designs. It makes less debris and helps with advanced chip layouts. This way is getting more popular because it can handle tricky wafer patterns. Granite equipment bases help plasma dicing stay accurate by lowering shaking and helping with careful moves.

Aspect | Mechanical Blade Dicing | Laser Dicing | Plasma Dicing |

|---|---|---|---|

Contact with Wafer | Yes | No | No |

Debris Generation | High | Low | Very Low |

Suitable Materials | Hard, brittle | Thin, special | Complex, narrow |

Risk of Chipping | Higher | Lower | Lowest |

Equipment Stability | Essential | Essential | Essential |

Note: Picking the best dicing way depends on the wafer, die size, and how many chips you need. Granite platforms and bases from SYIN Automation Technology Co., Ltd. help all these ways by keeping things steady and exact.

Wafer dicing equipment is very important in making chips. Each kind of equipment uses special technology to cut wafers into exact dies. The base of the equipment must be steady for good results. Granite platforms and granite equipment bases from SYIN Automation Technology Co., Ltd. give a strong and stable base. This helps the wafer dicing equipment stay in place and lowers mistakes during dicing.

Mechanical dicing saws have fast spinning blades that cut wafers on marked lines. These machines need a steady base so they do not shake. Vibrations can cause chips or cuts in the wrong place. Granite measuring platforms help keep the saw still. This means cleaner cuts and more good dies. Many companies use granite equipment bases because they stop shaking and keep the saw in the right spot. This helps make MEMS, ICs, and other new chips.

Laser dicing machines use a strong laser beam to cut wafers. The laser does not touch the wafer, so there is less chipping. This way also makes thinner cuts. Laser dicing needs the equipment to be very steady. Granite platforms help the laser stay lined up and not miss. For example, vision-guided systems work best with a solid, still base. This setup makes each die better and more alike.

Plasma dicing systems use chemicals to cut and separate dies. These machines do not need tape frames, so wafers are easier to handle. Plasma dicing uses ICP technology for strong plasma and better control. Workers can change the settings to get the best cuts. Plasma dicing does not use force or heat, so dies are stronger and have fewer problems.

Aspect | Description |

|---|---|

Tape and Tape Frames | Plasma dicing does not use tape frames, so wafers can be processed with normal carriers. |

Wafer Handling | No tape frames make it easy to handle wafers and do frontside work like lithography. |

Process Flow | Done after backside grinding, which keeps things simple and fast. |

Equipment Technology | Uses ICP for strong plasma, better control, and faster etching. |

Process Control | Settings like RF power, pressure, and gas can be changed easily. |

Damage and Quality | No small cracks or heat damage, so dies are stronger and more are made. |

Granite equipment bases also help plasma dicing machines stay steady while etching. This steadiness helps make sure each cut is exact and can be done again and again.

Buying good wafer dicing equipment helps for a long time. Companies get better cuts, less edge damage, and more good dies. New machines help make things like 3D ICs and system-in-package chips. Automation and smart features make work faster and save money.

Granite measuring platforms and granite equipment bases from SYIN Automation Technology Co., Ltd. help companies meet the tough needs of today’s wafer dicing. These products make sure wafer dicing equipment is accurate and reliable for the chip industry.

Wafer dicing is an important part of making chips. Using the right dicing method is needed for good results. Stable equipment, like a granite measuring platform or granite equipment base from SYIN Automation Technology Co., Ltd, helps keep the process steady. This makes sure each chip meets high quality rules. Companies that use steady and exact equipment get more good chips and better performance. To get the best chips, always pick trusted dicing solutions.

Tip: Using steady equipment and careful dicing methods gives better chips and saves money.

Wafer dicing means cutting a semiconductor wafer into many chips. Each chip is used as a single device. Special machines use granite equipment bases to keep the process steady and correct.

Granite measuring platforms give a flat and steady surface. This helps machines cut wafers very exactly. Less shaking means fewer mistakes and better chips.

Wafer dicing services use new machines and trained workers. They help stop chip damage and make more good chips from each wafer. This saves money and helps companies make more chips.

Manufacturers use mechanical blade dicing, laser dicing, and plasma dicing. Each way works best for certain materials and chip shapes. The choice depends on the wafer and the chip quality needed.

Yes. Granite equipment bases help with many careful jobs, like checking and measuring. They are also used in PCB drilling and optical path coupling, where steadiness and accuracy matter.